ROAD SIGNS FOR GUARD RAILS BARRIERS

Road signs are steel structural supported board with information for direction or warning fixed along road side at intervals of road and highway guard rail barriers. Made of steel post, support or aluminum material, with board, panels, tape, installed with accessories in concrete. We supply various designs of road signs to suit individual needs.

Popular road signs supplied with steel support and fittings.

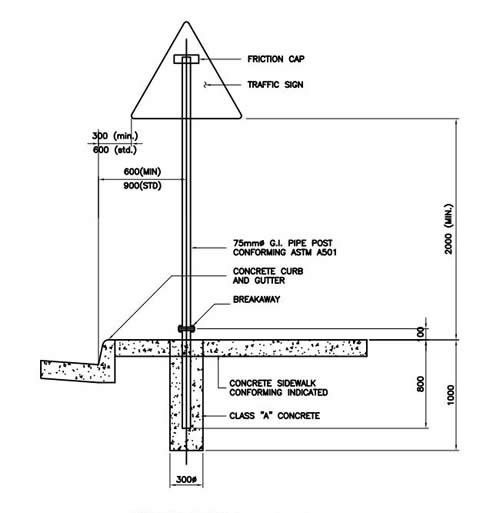

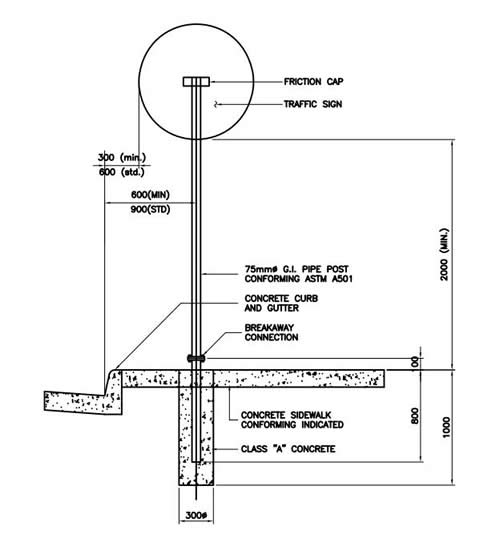

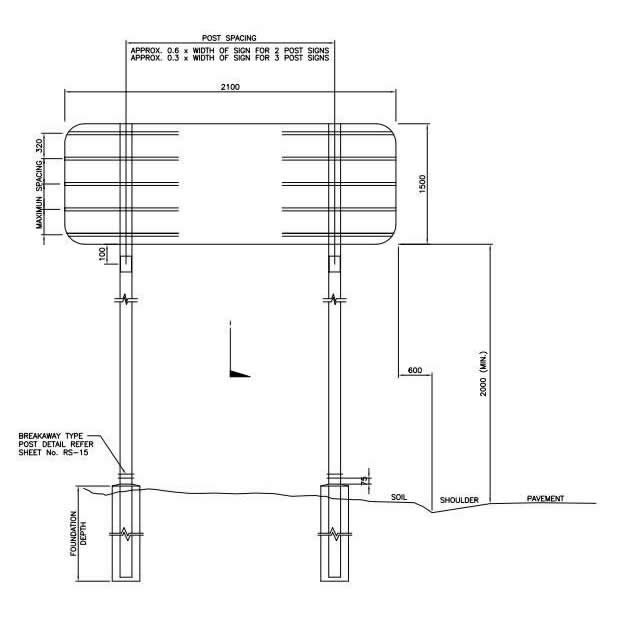

Road Sign Details-Triangular, Circular, Rectangular

Road Signs ( As per Drawing and Specs) - Triangular:

Road Signs ( As per Drawing and Specs) - Circular:

Road Signs ( As per Drawing and Specs) - Rectangular

SPECIFICATIONS

Structural Steel

Structural steel shall comply with the requirements of AASHTO M270 grade 250 or BS 4360 for the type of steel specified. All structural steel, including posts, shall be galvanized in accordance with the requirements of ASTM A123 or BS 729.

Steel posts shall comply with the requirements of ASTM A499 or BS 4848 Part 2.

Aluminum

Sheet Aluminum signs shall be constructed of material conforming to ASTM B 209M alloy 6061-T6 or alloy 5052-H38

Aluminum plate shall 2.0 mm in thickness.

Aluminum posts shall be of the sizes detailed on the drawings and shall conform to the provisions of ASTM B221M or BS 1474 (HE.9).

Bolts, Nuts and Rivets

Bolts, nuts, and washers shall be of the same material for each attachment, and meet the following requirements:

Bolts

ASTM B 209 2024-T4 Aluminum

ASTM A 307 Steel

ASTM F 593 Stainless Steel

Washers

ASTM B 209 2024-T4 Aluminum

AASHTO M 183 Steel

ASTM A 240 Stainless Steel

Nuts

ASTM B 211 2017-T4 Aluminum

ASTM A 307 Steel

ASTM F 594 Stainless Steel

Locknuts

ASTM B 211 2017-T4 Aluminum

ASTM A 307 Steel

ASTM F 594 Stainless Steel

Rivets

ASTM B 209 6061-T6 Aluminum

Post Clips

ASTM B 179 356 T-T6 Aluminum

Angle and Z-Bar

ASTM B 209 6061-T6 Aluminum

Strap & Mounting Bracket

ASTM A 412, type 201

All steel parts shall be galvanized per ASTM A 123. Steel bolts and related hardware shall be galvanized per ASTM 153.

Blind rivets used for fixing sign faces to square tubing framework shall be manufactured from or coated with a material that will not cause corrosion through electrolytic action. Blind rivets used for joining aluminum extrusions shall be hardened aluminum blind rivets.

Steel Plate

Steel plate shall be 2.00 mm thick and comply with the requirements of ASTM A525 or BS 4360.

Unless otherwise or shown on the drawings, steel plate shall be galvanized in accordance with the requirements of ASTM A525 or BS 729 (Heavy grade).

Particle Board

Particle board shall be an exterior grade timber particle board 12.7 mm thick, unless otherwise specified or indicated on the drawings, and consisting of a phenolated, resin bound timber particle core faced with a phenolated resin impregnated paper overlay, heat bonded under high pressure to form a homogeneous structure.

The particleboard shall comply with the relevant physical requirements for Type B-B NIST specification PS-1 or Type M board as specified in BS 5669.

Concrete

Concrete shall be manufactured and placed as specified in Division 8400. Normally Class 20/20 concrete shall be used for the erection of road signs, unless otherwise shown on the drawings or directed by the Engineer.

Fiberglass

Fiberglass reinforced thermoset polyester laminate panel shall be acrylic modified and UV stabilized for outdoor weather-ability.

Make fiberglass reinforced panels conform to the following mechanical and physical properties:

| Mechanical Property | Averaged Minimum Requirement |

ASTM Test |

| Avg. Tensile Strength | 69 MPa min. | D638M |

| Avg. Tensile Modulus | 8.3 GPa min. | D638M |

| Avg. Flexural Strength | 140 MPa min. | D790M |

| Avg. Flexural Modulus | 8.3 GPa min. | D790M |

| Avg. Compression Str. | 220 MPa min. | D695M |

| Avg. Compression Mod. | 9.7 GPa min. | D695M |

| Punch Shear | 90 MPa min. | D732 |

| Thickness | 3.4 +/-0.1mm | |

| Size, dimension < 3.7m | +/-3mm | D3841 |

| Squareness in 3.7 m length | +/-3mm | D3841 |

| Surfaces, top and bottom | Smooth | |

| Color, visually uniform gray, MunselR range | N.7.5/ - N.8.5/ | |

| Coefficient of lineal thermal expansion | 0.01µm/mm/°C max. | D696 |

| Impact resistance, -54 to100°C | 0.54 kg from 18.3 m | D3841 |

| Flame resistance | 25 mm max. | D635 |

| Weather resistance, 3000 +/-100 h | grade II min. | D3841 |

Retro-Reflective Material

Retro-reflective material shall be supplied in engineering grade which material shall conform to the requirements of ASTM D 4956 or BS 873 Part 6. It shall be selected from the Ministry’s list of approved retro-reflective materials.

The material shall be supplied with a pressure sensitive or heat applied adhesive backing protected by a removable liner.

Paint

Paints for road signs shall be selected from the Ministry’s list of approved road sign paints. Project acceptance will be based on the appearance of an approved brand name on the container label. All paints and solvents shall conform to Federal air pollution regulations, including those for the control (emission) of volatile organic compounds (VOC) as established by the designated environmental protection agency.

The paint shall be delivered to the Site in sealed containers bearing the name of the manufacturer and the type of paint.

The viscosity of the paint shall be such that it can be applied without thinning.

Corrosion Protection Tape

Corrosion protection tape used between aluminum and steel shall be an quality approved material.

MANUFACTURING OF ROAD SIGN FACES AND SUPPORTS

Road Sign Faces

Road sign faces shall be manufactured in strict accordance with the details of the prevailing Traffic (Signs) Regulations or as shown on the drawings. They shall be manufactured from either steel plate, aluminum plate or fiberglass according to what is specified. Wherever possible, road sign faces shall be manufactured as one unit. Road signs that are too large to be transported as one unit can, with the approval of the Engineer, be manufactured in sections. The completed sections shall be assembled in the shop prior to delivery to ensure that all sections fit together properly and that the legends are properly spaced and aligned. Joints in sign faces shall only be provided at locations and to details approved by the Engineer. The signs shall be faced with Engineering Grade retroreflective material.

Direct contact between aluminum plate and steel supporting framework shall be avoided by the application of corrosion protection tape to the sign face over the contact areas.

Welding

All welding of steelwork shall be carried out in accordance with the standards laid down in AASHTO/AWS D1.5 Bridge Welding Code or BS 5135. Welding shall be done before painting.

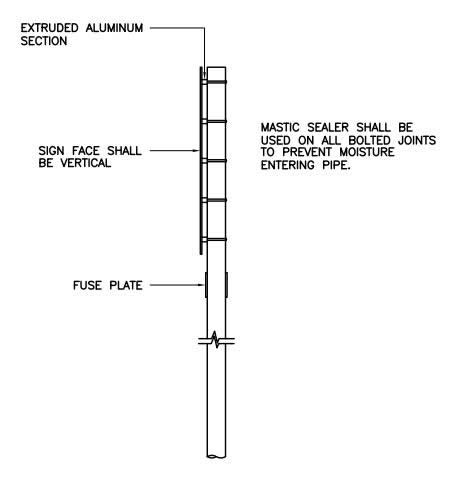

Aluminum Extrusions

Aluminum extrusions for sign faces shall be joined together by blind rivets or bolts. They shall preferably not be joined longitudinally but, if this cannot be prevented without excessive waste, they shall be joined neatly and joints staggered. No sections shorter than 500 mm shall be used.

Where aluminum extrusions are to be faced with retro- reflective background material, it shall be pre-applied to individual sections before assembly with the material taken around the face edges of each extension for at least 10 mm. Retro- reflective material shall be heated to facilitate binding around edges without damaging the material. Where possible, letters across the joint between two extrusions should be avoided.

Galvanizing

Where the galvanizing of structural steel signboard frames and signboard supporting structures is specified, it shall be done as far as is practicable after welding. Where, however, this is not practicable, the steel sections shall be galvanized before assembly and then welded. All welds shall be thoroughly cleaned, loose material removed and dressed after which the welds shall be coated with two coats of an approved zinc-rich paint.

Galvanized steel posts will not require painting unless stated.

Where details for the construction of sign faces, the framework of the sign faces and the attachment thereof to the supporting framework are not shown on the drawings, the Contractor shall design these himself and submit the details to the Engineer for approval before manufacture.

PAINTING

Colors, Symbols and Legend

Paint colors, symbols, legends and borders used on road signs shall comply with the regulations of prevailing Traffic (Signs) Regulations.

The colors and shades shall conform to the colors and shades specified in the Ministry’s approved list of road sign paints.

Preparation of Surfaces and Application of Paint

Immediately before painting, prepare the surface according to the following:

- Clean the surface

- Remove dirt, dust, and other contaminants from the surface using methods recommended by the paint manufacturer

- Thoroughly dry the surface

- Determine that the surface temperature is between 10 and 40°C.

- Determine that the surface temperature is 3°C or more above the dew point according to ASTM E337

- Determine that the humidity is 85 percent or less, unless specified otherwise on the manufacturer’s product data sheet

Unless otherwise specified, aluminum and galvanized steel road signs will not require painting.

Time of Painting

Painted shall not be carried out more than six months prior to erection.