Highway Guardrail - Guard rail system for highway road, bridges and emergency median opening safety

Highway Guardrail is a metal beam passive barrier system mostly processed from corruguated steel plates 10 gauge and 12 gauge, through flattening, punching, hot dipped galvanizing and shearing processes, into solid metal beams with symmetrical shapes of waves, with a radiums ranging from 5’ to 60’, specially installed along the highway road side, bridges, median openings and viaducts for safety and reducing the potential danger of vehicle crashing.

We are an established manufacturer and supplier of matal beam Highway Guardrails in sets, and our products are manufactured with all the latest traffic regulations and signs available in every country to make the road and bridge safer.

We have worked as contractor and supplier for Highways, Road Development, Urban Planning, Transportaion Development Authorities and related companies in many countries for the supply of highway guard railing products, in Africa, and Asia, Europe and America. We also supply trading company, and contracting co. in supplying and installing a range of Aluminium and Steel guard railing system for Highway and Expressway Road Safety.

Design of Guard Rail Layout - We help design, furnish and install Highway Guardrail Project

The spacing of the guard rails shall be revised at bridges, culverts, lighting post, traffic sing board and other special sites.

Crash cushion barrier shall be provided at each exit locations.

Wire cables can be used.

Chain link fence can be used for highway openings.

Our Highway Guardrails is supplied meeting following Quality / Standards:

Guardrails

Dimensions of guardrails and terminal sections as required or per drawings.

Guardrails shall be supplied together with all bolts, nuts, washers and fixing materials required other than bolts for fixing to posts.

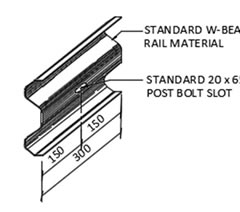

The W-beam rail element, backup plates, and terminal sections, channel rail and splice plate shall be in conformance with AASHTO M 183.

Beam rail elements and terminal sections shall be galvanized in accordance with AASHTO M 180, Class A, Type 2. The minimum average weight of Zinc coating shall be 2 ounce per sq. foot. Bolts, nuts, washers, plates, rods and other hardware shall be galvanized in accordance with ASTM A 153.

OR

Guardrails shall comply with the requirements of BS 149. When galvanized guardrails are called for on the drawings or in the Bill of Quantities, a hot-dip galvanized zinc coating that complies with the requirements of BS 763 for coatings on Type A1 articles shall be applied.

All bolts, nuts and washers shall have a hot-dip galvanized zinc coating that complies with the requirements of BS 763 for coatings on Type C1 articles. Galvanized guardrails shall not be nested when stacked for storage.

Guardrail Posts

Box beam posts shall conform to AASHTO-AGC-ARTBA A Guide to Standardized Highway Barrier Hardware, 1995 Edition.

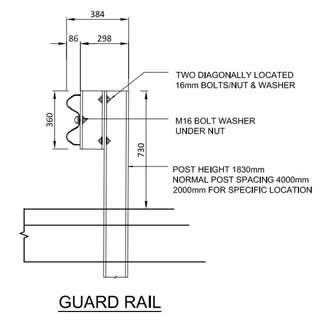

Posts shall have a top diameter of at least 150 mm. Posts with a top diameter up to 230 mm will be acceptable, provided that posts of widely varying diameter are not used together in the same length of guardrail.

Posts shall be drilled and shaped as shown on the drawings and provided with the necessary bolts, nuts, washers and spacer posts for fixing.

Highway guardrail products:

Highway guardrail with trailing anchorage

Galvanized W-beam guardrails for highway protection

Guardrail Take-Off

10 gauge metal beam guardrail

12 gauge curved guardrail from 5' to 60' radii, a wide variety of terminal end

Highway guard rails for highway projects with bridges, emergency median opening and viaducts

Guardrail with Trailing Anchorage - for Highway and Highway Bridges Safety

This syetem is a post spacing guardrail sets with steel post trailing terminal, a longitudinal highway barrier designed to reduce the severity of run-off-road collisions.

Highway

Guardrail with guardrail trailing anchorage composed of through rail element, guardrail post, strand wire cables. 3/4" stranded wire cable and accessories.

steel rail post W6x9.

Highway Guardrail as per attachment.

Guardrail Take-Off - W-Beam, 6'3" Galvanized

Description

W-Beam, 6'3" Galvanized

End Piece

5/8" x 1-1/4" Splice Bolt, Galvanised

2" x 1" Galvanized Washer

3" x 1 3/4" Rectangular Washer

5/8" x 9 1/2" Hex Bolt & Hex Nut

1-3/4" x 11/16" Galv Steel Washer

5/8" Round Washer Galv.

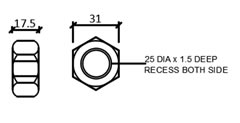

5/8" x 1-1/4" Recess Nut

Steel Guardrail Post W6x9, 6'

Steel Guardrail Post W6x9, 1'-2"

Guardrails Used for Highway Bridges - Bridge Parapet Barrier

Highway bridge guardrail barrier is a kind of parapet wall barrier designed for construction of city / urban outer ring road bridges. We design and supply highway bridge parapet barrier for contractors and tender projects according to drawings and requirements.

Bridge rails including:

Guardrails on Steel Post Galvanized Steel

End sections

Spare parts

Design: Lap guardrail for traffic flow control

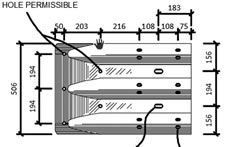

Drawing reference: Highway Bridge Parapet Wall Guardrails System

Galvanized W-beam Guardrails and Post for Highway Road Protection

Guard railings: Steel Guardrails Hot Dip Galvanized

Post: Sigma post

With yellow signs on the end of the guardrails, applied to antennas.

Highway Guardrail Sigma Posts:

Drawing reference:

Sigma Post for W Beam Guardrails

1900x100x55x4mm sigma steel posts

Highway guardrails popularly used in European countries

Drawing reference:

Guardrail system images reference

Highway W Beam Guardrail Barrier and Accessories, Terminal Options- Typical Designs

Common design for highway, expressway, free way:

2m & 4m Interval

3D,3B,3E,3G End Terminals

Emergency opening

Delineators types such as 1,2,2EB

SPECIFICATIONS

General

The Guardrail system, including all components conform to Highway Design Standards, for road and bridge construction 2017, issued by the Ministry of Transport and Communication, or related authorities of the applied target country.

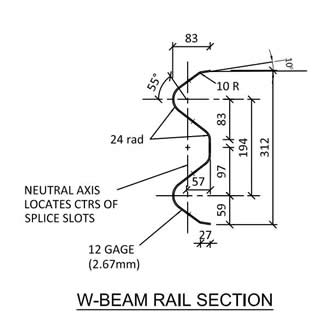

W Beam Material

The Beam is manufactured from high quality Hot Rolled coils to AASHTO M 180 by continuous forming and punching system.

Post & Spacer Materials

The post & spacer is fabricated from made out of I Beam WB 150x13.5 kgs/m confirming to ASTM A-36

Bolt Nut & Washer

All fixing bolts, nuts & washers conform to ASTM A 325/Astm A 563 M as applicable and are Hot Deep Galvanized to ASTM 153M

Galvanizing

The Guardrail will be Hot Dip Galvanized according to ASSHTO M 180, Type -2 and posts will be Hot Dip Galvanized to ASTM A 123M

DETAILS

W Beam Guardrail Standard section including block and bolts:

(supplied in sets of guardrail length of 3.81m c/c. Each set includes :

1) 1 no 310mm, high 2 wave guardrail, 4.13m long and 2.8mm thickness.

2) 1 no 310X300mm long backing plate, 2.8mm thickness

3) 2 nos spacer block WB 150X13.5 kg/m 360mm long

4) 9 sets of bolts, nuts & washers

Guardrail concrete barrier transition:

Each Set includes:

1)W beam 12.5m long.

2)13nos posts

3)13nos spacer blocks

4)6 nos of backup plate

5)1 No . Shoe

6)110 sets of bolts, nuts&washers

(Rawl Bolts Excluded)

Highway Guardrail End Anchorage Type -1:

Each Set Includes:

1) Guardrail Section Of 1.905m long or desired length

2) 2 nos posts of WB 150@ 13.5kg/m

3) 2 nos spacer Block of WB 150@13.5kg/m

4) 6 nos of backup plate

5) 19mm Dia Anchor Cable

6) 2 Nos Shelf Angle

7) 1 Nos Bearing Plate

8) 1n No Struct & Yoke Assembly

9) 1 No Back up Plate

10) 2 Nos Steel Tube Anchor

11) 2 Nos Soli Plate

12) 1 No Terminal Section Type-1 ( Curved Type)

13) 36 Sets Of bolts , nuts& washers

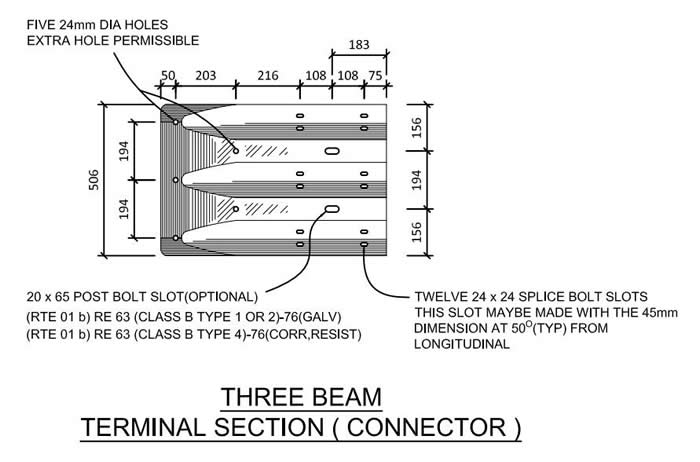

Guardrail Terminal Section – Option 1

End Anchorage Type -2 :

Each Set includes:

1) 1 no Guardrail section 1.905m long

2) 2 nos posts

3) 2 nos spacer blocks

4) 1 No.Anchor Plate

5) 19mm dia Anchor Cable

6) 32mm dia X990mm Anchor Cable Rod

7) 1370mm long WB 150 posts for embedment

8) 1 no Terminal Section Type-2 (Fish Tail)

9) 1 no back up plate

10) 34 sets of bolts , nuts & washers

Guardrail Terminal Section – Option 2

Simple Terminal Type -2 :

1) Fish Tail for W Beam

2) 1 no post

3) 1 no spacer block

4) 11 sets of bolts , nuts & washers

W Beam Guardrail post of WB 150X 13.5kg/m

2 sets of bolts , nuts & washers

Guardrail Reflectors , double face, Swarflex Austria

Supply Of Impact Attenuators With Base Frame And Bushes

Model – SMA 110P, manufactured by M/s. Smart Cushions Italy , Tested to 130km/hr,

As per EN 1317-3 standards and tested to NCHRP 350

Installation of the impact Attenuators including Supply of reinforcements steel cage and transitions.

Barrier reflector for Concrete Barrier

Detailed item list for the project:

| Item | Finish |

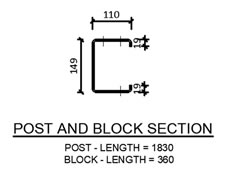

| "C" Posts | Galvanised steel, standard or as required |

| "C" Block | Galvanised steel, standard or as required |

| Round bar | Galvanised steel, standard or as required |

| 3 Wave beam | Galvanised steel, standard or as required |

| 3 Beam terminal section | Galvanised steel, standard or as required |

| Backup plate | Galvanised steel, standard or as required |

| Rectangular washer | Galvanised steel, standard or as required |

| Button head oval shoulder M16*35 | Galvanised steel, standard or as required |

| Button head oval shoulder M16*50 | Galvanised steel, standard or as required |

| M16*50 Hex head | Galvanised steel, standard or as required |

Highway Guard Rail, Bridge Rail & Emergency Median Opening Fencing

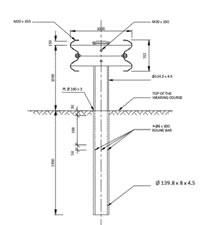

This highway project consists expressway, bridges, emergency openings, and viaducts.

Highway / Expressway Guard Rail Furnishing and Installing Details:

Details of the guardrails

Typical Details of Guard Rail Installation

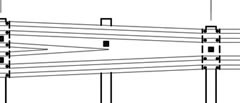

W Beam Median Guard Rails fixed with bolts, c post, c block

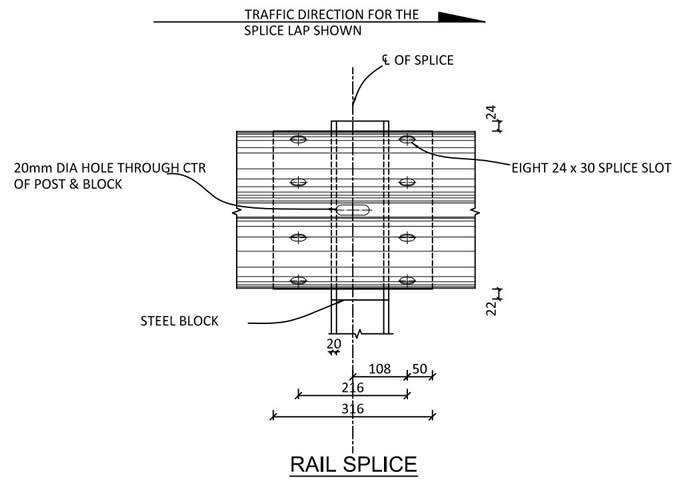

All w-beam splices, and splices of terminal connectors to W beam railings shall be lapped in the direction of traffic unless otherwise requested.

Material type and shape of posts and blocks are the same throughout the project, except when specified posts and blocks are specified such as at end archorage and box culverts.

Open sides of C posts and blocks is face away from approaching traffic in roadside installations.

The fixing arrangement of the guard rails shall be proposed by contractor and approved by the engineer.

Center Median Guardrail Condition

Guard Rail Installation at Obstructions

All w-beam splices, and splices of terminal connectors to W beam railings shall be lapped in the direction of traffic unless otherwise requested.

Material type and shape of posts and blocks are the same throughout the project, except when specified posts and blocks are specified such as at end archorage and box culverts.

Acceptable alternatives to W150x13.5 posts and block are w150x12.6 rolled or welded beam, or bent plate C. The welded beam shall be in accordance with ASTM A769 with the same shape and weight per foot as a W150x12.6 or W150x13.5.

Open sides of C posts and blocks is face away from approaching traffic in roadside installations. In double clicked median installation the open side shall face in the same direction.

Guardrail Splice Details

Drawing reference:

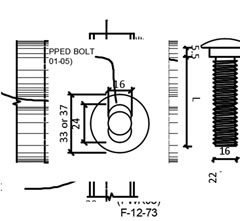

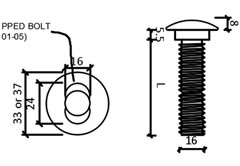

HEX NUT, WASHER

| DIAMETER &TYPE | LENGTH L |

THREAD LENGTH |

INTENDED USE | AASHTO-AGC-ARTBA STANDARD NUMBER |

NO BOLTS,NUTS & WASHER |

| 16mm BUTTON | 35 | FULL (30) | ALL RAIL SPLICES | F-3(1¼”)-76)(FBB01) | 8 PER SPLICE |

| HEAD,OVAL SHLDR | 50 | MIN 45 | FASTEN RAIL TO STEEL BLOCK | F-3 (2")-76)(FBB02) | 1 PER POST |

| 16mm HEX HEAD | 50 | FULL | FASTEN STEEL BLOCK TO POST | F-8-76 (FBX 16a) | 2 PER BLOCK |

| PART | MATERIAL SPEC | GALVANIZING SPEC | CORROSION- RESSISTENT SPEC |

| W-BEAM RAIL BACK-UP PLATE. TERMINAL SECTIONS THRI - BEAM RAIL | AASHTO M180 CLASS A ORB | AASHTO M 180 TYPE 1 OR 2 |

AASHTO M 180 TYPE 4 |

| BENT PLATE ("C) POST & BLOCK |

ASTM A 570M GRADE 36 ASTM A 36M |

AASHTO M 111M | AASHTO M 222M (ASTM A 588M) |

| NUTS,BOLTS & STUDS FOR GENERAL USE | ASTM A 307 | AASHTO M 232, CLASS C OR ASTM B 695 CLASS 50 |

|

| HIGH STRENGTH BOLTS & NUTS |

ASTM A 325 | ||

| HIGH STRENGTH STUDS & NUTS |

ASTM A 449 | ||

| ROUND STEEL WASHER |

ASTM F 436M | ||

| RECTANGULAR WASHER | AASHTO M 180 | ||

| OTHER FITTINGS | ASTM A 36M | AASHTO M 111M | |

NOTES:

1. All dimensions are in millimeters unless otherwise indicated.

2. Guardrail shall confirm to the following requirement:

2.1 steel rail shall be made from steel of thickness not less than minimum thickness specified for each class of rail and shall be galvanized with the minimum weight of zinc coating according to the specification given in table below.

2.2 The galvanizing of bolts,nuts,washer and similar threaded fasteners shall be in accordance with standards given.

3. The tabulation of guardrail will specify the type of corrosion protection:galvanized or corrosion-ressistant steel.

4. Steel post and blocks shall have the same corrosion protection as specified for the metal beam rail punching,drilling. Or cutting will not bepermitted after galvanizing.

5. S - refers to span between two poles and shall be as specified in the guard detail drawing.

6. Working drawing shall be submitted to the engineer the detail,dimension according to the manufactures specification.

Guard Rail Anchorage, Structures, Details

Anchorage Details:

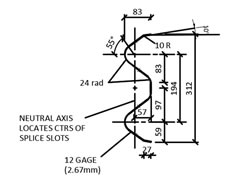

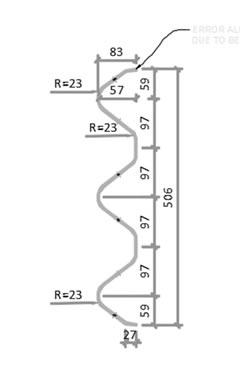

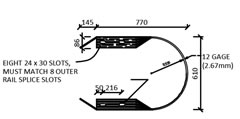

Thri-Beam Rail, Rail Thickness 2.67mm Class A

Rail thickness: 2.67mm

Finish: Galvanized

Rail bending length allowed error indicated as in drawing

W150 x 13.5 x360 Block

C post W150x13.5x1830

Nested three beam type 3G

Standard washer and nuts on 2-16mm diameter post bolts

Guard Rail Details at Median Openings

SPECIFICATION

Description

The highway project usually consist of furnishing and installing the guardrail and emergency median openings (Chain link fence designed at approx. 2 km intervals).

The work for guard rails shall include all required metal corrugated beam, guardrail posts, guardrail hardware, painting if required and all the processes necessary to complete the work.

The chain link fence for median opening consists of chain link panels, steel posts and concrete foundations.

Materials

Guardrail Materials shall follow either BS or AASHTO standards.

If the material is based on BS, materials used shall be as given below: Corrugated beams and posts: BS EN 10025, Grade S 275

Untensioned corrugated beam shall be assembled in accordance with BS 7669: Part 3, Section

Guardrail shall follow AASHTO M 180, Corrugated Sheet Steel Beams for Highway Guardrail for the specified class and type of corrugated guardrail elements.

Galvanization: AASHTO M 232.

Guardrail posts: ARTBA Bulletin No.268, A Guide to Standardized Highway Barrier Rail Hardware.

The guardrail shall be zinc coated corrugated-sheet steel beam rail elements according to AASHTO M 180 or equivalent.

Type of guardrail: Type l: Zinc coated 550 g /sq.m. Minimum single-spot.

Class of guardrail:.CIass A, Base metal nominal thickness, 2.67 mm.

Shape: W-beam.

The guardrail shall be zinc coated steel of thickness not less than 10 or 12 gauge as shown on the Drawings. The steel shall elongate not less than 12 percent in a 50mm gauge length under tensile tests. Rail elements shall meet the strength requirements of Table 703.1 Other specification shall follow requirements in AASHTO M 180.

W Beam and Hardware Illustrations:

| Sr No | Description | |

| 1 |  |

Gauge: 12 (Galvanised) |

| 2 |  |

"C" PostsGuard rail post Steel C post and c block |

| 3 |  |

Round bar |

| 4 |  |

3 Wave beam |

| 5 |  |

3 Beam terminal section |

| 6 |  |

Transition section |

| 7 |  |

Button head bolt with oval shoulder M16*35 |

| 8 |  |

Button head bolt with oval shoulder M16*50 |

| 9 |  |

M16*50 Hex head |

| 10 |  |

Backup plate |

| 11 |  |

Buffer |